My Projects

A dream does't become reality through magic: It takes sweat,determination and hard work

- Colin Powell -

Anti-Fire Automated Vehicle

|  |  |  |

|---|---|---|---|

|  |  |  |

|  |  |

Automated fire fighting vehicle

About this Project

Background

&

Motivation

-

Our project is a vehicle designed to avoid obstacles and fight fires. The vehicle is controlled by a PSOC, run with the aid of 2 motors, and detects obstacles with the help of ultrasonic sensors. A GUI is also made on LabView to show the functionality of the vehicle and to switch it on or off.

-

The project is motivated by the devastation of the California wildfires caused. We believe that the use of autonomous robots like ours would help prevent wildfire to spread and also help keep them in control or extinguish them. This would prevent putting the lives of firefighters at risk and hence decrease the cost in human lives of the horrible natural disaster.

Skills

-

Programming in C++ language to communicate with Psoc.

-

Developed a graphical user interface (GUI) by using LabView for user to interact.

-

Designed and built the vehicle by using solidwork and 3D printer.

-

Laser cut the base of the vehicle.

-

Built electric circuit of the vehicle.

Technical

&

Software

set

-

Psoc

-

C++

-

LabView

-

Solidwork

-

Laser cutter

-

3D printer

-

Electronic component assembly

Interactive Spine Brace

About this Project

Background

&

Motivation

-

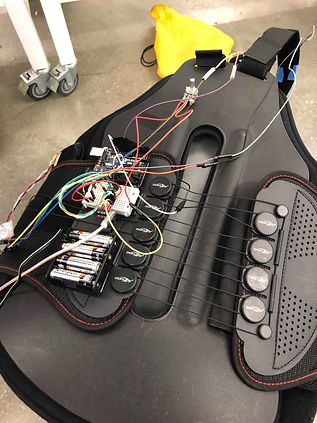

Aiding healing progress for spine brace user has been our goal for this project. This project will let the spine brace to alert the user if they do something that might harm their healing progress. According to an interview that we did, there are 3 general activities that might harm spine patient healing progress which are spinning, bending and lifting. With the time and resources that our team have, we focus on lifting activitie since most patient can’t really tell if they over exert their spine. We installed some sensor to alert the user via both vibration and LED if they lift something that is heavier than the their doctor’s advice.

-

We interviewed a spine patient who went to multiple surgery to fix his spine. He mentioned that this project will really be helpful for his healing progress since sometimes he doesn't even realize he did activities that might harm his healing progress. With an interactive brace that can always alert him to be more cautious, it will reduce the probability of him to redo spine surgery that is both painful and expensive.

Skills

-

Programmed in Arduino

-

Installed pressure sensor, LED and vibrator

-

Built electric circuit

-

Redesign the spine brace to add some new features.

Technical

&

Software

set

-

Arduino

-

FSR sensor

-

Electronic component assembly

|  |  |  |

|---|---|---|---|

|  |

Informative Spine Brace

Control of Unmanned Aerial Vehicle

|  |  |  |

|---|

Unmanned Aerial Vehicle

About this Project

Background

&

Motivation

-

Analyzed and modelled drone flight to create a controller for it. We are using C++ to programmed the drone flight. We did some analysis to study the sensors in the drone and create a controller to adjust the force applied by each of the drone’s blade. We successfully make it hover and land on a targeted location.

-

Aerial vehicle’s industry has been blooming for this past years. In order to catch up with this technology flow, a deep knowledge about drones will benefit us. With the knowledge gained, we can make innovation on shipping sector and even transportation sector.

Skills

-

Programmed in C++

-

Created a PID controller

-

Flying drone

-

Knowledge in fluid, physic and math

Technical

&

Software

set

-

C++

-

PID controller

-

Virtual Box virtual machine

-

Eclipse

-

Sensor

-

Flying drone

Prosthetic Hand

|  |  |

|---|

Prosthetic hand

About this Project

Background

&

Motivation

-

Designed and built prosthetic hand with improved functionality. We designed a low cost mechanism that can allow the prosthetic hand to have specific control on each finger. Then we built the prototype using 3D printer.

-

Unlike the existing prosthetic hand that allow the user to have control for each of their finger, our designed prototype is much cheaper. We are not using any sensor or electronic component to move the finger. We believe that a full mechanical system will reduce the cost of the prosthetic hand while having the same functionality.

Skills

-

Designed in Solidwork

-

Built prototype using 3D printer

Technical

&

Software

set

-

Solidwork

-

Ultimaker and type A 3D printer

-

Machining Skills

Phone case with GoPro mount interface

About this Project

Background

&

Motivation

-

Designed and built phone case that has interface with GoPro mount. We designed a mechanism that can be installed into any GoPro mount. This mechanism is detachable to produce a slim phone case.

-

The advance of camera phone nowadays is good enough to replace GoPro. With our phone case, we can replace GoPro with our phone but can still using GoPro mount that is versatile.

Skills

-

Designed in Solidwork

-

Built prototype using 3D printer

Technical

&

Software

set

-

Solidwork

-

Ultimaker and type A 3D printe

|  |  |  |

|---|

Laundry Machine Notifier

About this Project

Background

&

Motivation

-

Replacement for smart laundry machine with a non - invasive and cheap device is the goal of our project. Utilising vibration from the laundry machine, we analyze the vibration and process the data using microcontroller. Then, with the processed data, we send relevant information to the user in terms of availability of the machine or state of the machine.

-

Shared space or communal living make laundry chores become hard because of limited number of the laundry machine. The laundry machine provided usually is not advanced enough for it to send notification to user. With the device that we created, we can install it non invasively to any laundry machine and it will let the user know the condition of the machine if it is available and even tell the user if it still spinning or rinsing.

Skills

-

Programmed in C++ and Python

-

Implemented IOT in our device

-

Designed in SolidWORK

-

Built electric circuit

Technical

&

Software

set

-

C++

-

Python

-

Internet Of Things (IOT) implementation

-

3D printing

-

ESP32 microcontroller

-

Electronic component assembly

|  |  |  |

|---|---|---|---|

|  |  |  |

Laundry Machine Notification

About this Project

Background

&

Motivation

-

In this experiment, the lift force, drag force and criterion for aerodynamic stalling of airfoils NACA 4412, NACA 23012, and NACA 63-210 are explored. These airfoils are tested in a wind tunnel at varying angles of attack and wind speeds in order to gain a better understanding of the influence of these two variable factors on the performance of airfoils and aerodynamic stalling. Additionally, the influence of vortex generators are infused into the scope of the experiment in an effort to gain a better understanding of factors that mitigate aerodynamic stalling.

Skills

-

Research on the aerodynamic characteristic of Airfoil

-

Analysis data in MATLAB

-

Designed in SolidWORK

-

Built airfoil prototype

-

Alter AOA and wind speed to characterize each airfoil

Technical

&

Software

set

-

MATLAB

-

LabVIEW

-

SolidWORK design

-

3D printing

-

Electronic component assembly